+91 9699199208

Spring Coiling Machine Manufacturers in Pune - Stalwart Machinery LLP

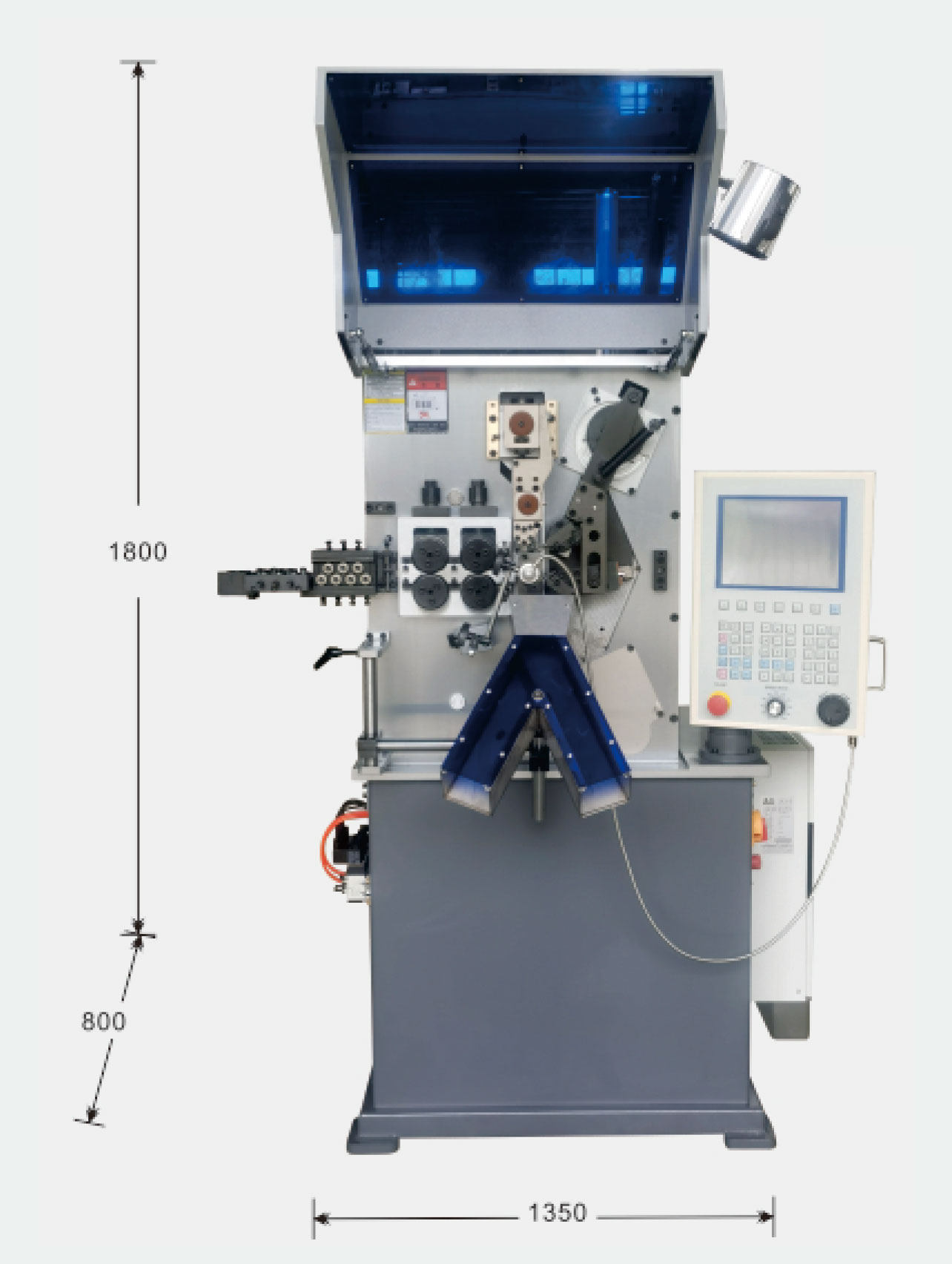

Stalwart Machinery LLP is a leading Spring coiling machine manufacturers in Pune and suppliers in Pune, We are committed to delivering high-quality spring coiling machines designed to manufacture precision-engineered springs by accurately coiling metal wire, that is used to manufacture and produce the spring by coiling metal wire with more accuracy.

We have used new technological updates in these springs coiling machine and it gives higher productivity as compared to manual labor. These are mainly used in automotive industrial sectors for making suspension spring, valve springs and clutch springs also. The use of our new CNC spring coiling machine increases the performance in large industrial sectors and gets work done more precisely. Let’s check out its multiple types of machines, it is using benefits and applications also!

Types of Spring Coiling Machine

As a leading spring coiling machine manufacturers in Pune, we are providing the new technological machines that are highly useful in multiple applications. Here we have listed down some types such as:

- Dual-Function Coiling Machines: We have engineered Dual-Function Coiling Machines to remove your labor and time from your production cycle. The machines cut and coil in a single solid continuous cycle with no other tooling. With the duo, you can anticipate turnaround time to rise and operations to be improved.

- Mechanical Spring Coiling Machines: We continue to refine our Mechanical Spring Coiling Machines to offer cost-effective solutions without compromising on quality. These machines are best suited for small to medium-scale production units that need a strong and durable machine. We’ve recently added frequency drives and upgraded cam settings to improve their accuracy and stability.

- Spring Automatic Coilers: We manufacture Automatic Spring Coilers for producers who require speed with no compromise on control. Machines enhance production processes by interfacing with electronic counters and wire feed adjustment to offer smooth process. Shut-off components reduce lost time and promote safety.

- CNC Spring Coilers: Our CNC Spring Coilers are pre-fitted with multi-axis servo driver systems to provide you with maximum accuracy per coil. They are ideal for mass production when accuracy and consistency are required. With the real-time programmable parameters as well as the auto length sensing, we enable manufacturers to manage high demand for complex spring geometry with ease.

Technical Specifications of Spring Coiling machine

For more technical information about our Spring Coiling Machine, we have mentioned below a technical chart such as:

| Specification | Details | Advanced Feature / Note |

|---|---|---|

| Machine Type | CNC / Automatic / Mechanical | Multi-axis servo options available |

| Wire Diameter Range | 0.15 mm to 8.0 mm | Fine-wire capable (for medical & electronics) |

| Spring Types Supported | Compression, Tension, Conical, Torsion | Custom profiles programmable via HMI |

| No. of Servo Axes | 3 to 8 axes (depending on model) | Enables complex geometries and fine adjustments |

| Wire Feed System | Servo Motor Controlled | Auto tension control with feedback loop |

| Max Coiling Speed | Up to 600 Coils/Minute | Speed varies with wire gauge and spring complexity |

| Length Measuring System | Laser / Encoder Based | High accuracy with ±0.1 mm tolerance |

| Programming Interface | Touchscreen HMI with USB & Ethernet | Remote access + multi-language support |

Features of Spring Coiling machine

Being the best Spring coiling machine suppliers in Pune, our all types of machines are known for their advanced features and gives multiple types of benefits such as:

- Smart CNC Programming Interface: We are also fitted with HMI ergonomic touchscreens for easy programming of the spring size and form. Multiple coil profiles in our machines ease the set-up times for repetitive orders. There is smart ease in programming the complex coils in order to readily change product lines.

- Real-Time Error Detection & Auto Correction: We have incorporated sophisticated sensor-based systems monitoring wire tension and coiling patterns under usage. The sensors automatically detect any deviation and correct them before they can affect the end product. This means less rejection rate and more usable production per batch.

- Servo-Controlled Wire Feed & Coiling Tools: We employ servo motors in wire coiling and wire feed machines so that precision at each step is guaranteed. The technology provides uninterrupted output which is extremely critical in the manufacturing of aerospace and medical devices. Even instantaneous change in the size of the springs is facilitated by the servo control without halting production.

- Easy Customization through Modular Design: We have come up with modular-based machines just for you, so you could add and upgrade as per the changing needs of your production. From adding feeding units to accommodating post-processing gear, we present you with ease. You may even swap the parts of the machine in such a way so that you process spring differently without having to recreate it entirely.

Applications of Spring Coiling Machine

One of the leading spring coiling machine manufacturers in Pune, these machines are largely used in various kind of applications such as:

- Medical Device Manufacturing: We supply precision coiling of springs for medical devices such as catheters biopsy instruments and surgical instruments. They need micro-level accuracy and flawless surface finish. Our equipment is capable of coiling very thin wire with smooth tensioning so that they don't get bent.

- Consumer electronics: We facilitate fast production of small springs utilized in electronic components like battery contact connectors and switches. The parts must be precise and small with room for zero mistakes. Our small machines facilitate fast production with the ability to repeat.

- Aerospace and Defense: We produce machinery that can produce high-performance light springs employed in aerial and military aircraft. Failure-resistant springs and those resistant to tough conditions are needed. Our CNC samples possess the accuracy to sustain tolerance below close spec.

- Automotive Industry: We supply the automotive market with machinery that manufactures suspension springs brake return springs and seat mechanism components. These need to be extremely strong and accurate to the safety standards. Our equipment ensures every single spring to precise load-carrying specifications with no room for mistake.

We, Stalwart Machinery LLP is one of the reputed Spring Coiling Machine manufacturers, suppliers based in Pune, India. We are dedicated to delivering high performance, customized Spring coiling Machine, Our offered Machine is Specialized industrial machine used to produce coiled springs from metal wire. It operates by feeding wire through a set of rollers and guiding it around a coiling point to form precise helical shapes

Frequently Asked Questions (FAQs)

A CNC spring coiling machine is an automated system that precisely forms coil springs using computer-controlled mechanisms.

A spring coiler feeds wire through rollers, bends it into coils using servo-driven tools, and cuts it to the desired length.

A spring machine is used to manufacture various types of springs for industries like automotive, aerospace, medical, and electronics.