+91 9699199208

Spring Coiling Machine Manufacturers in India

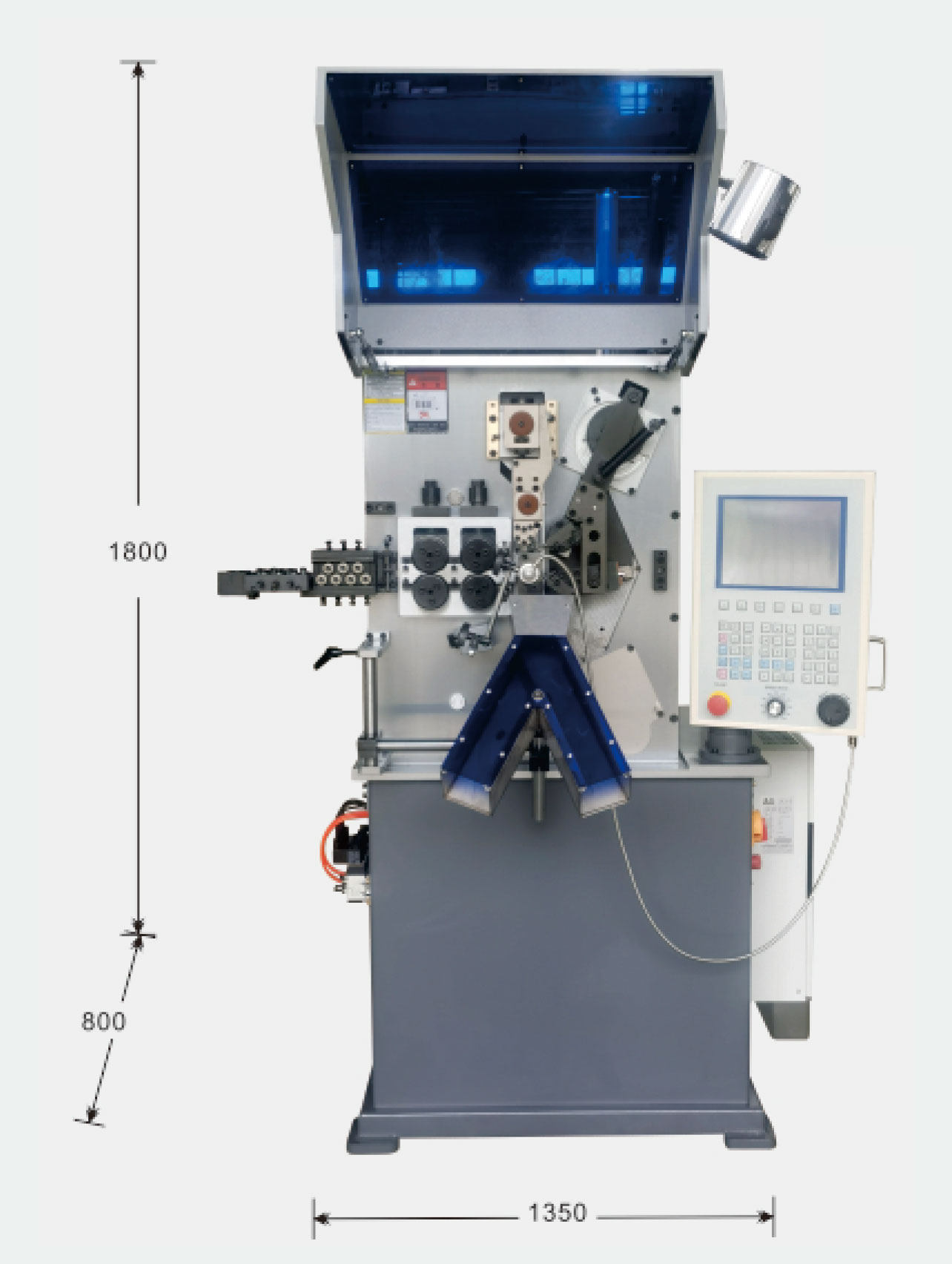

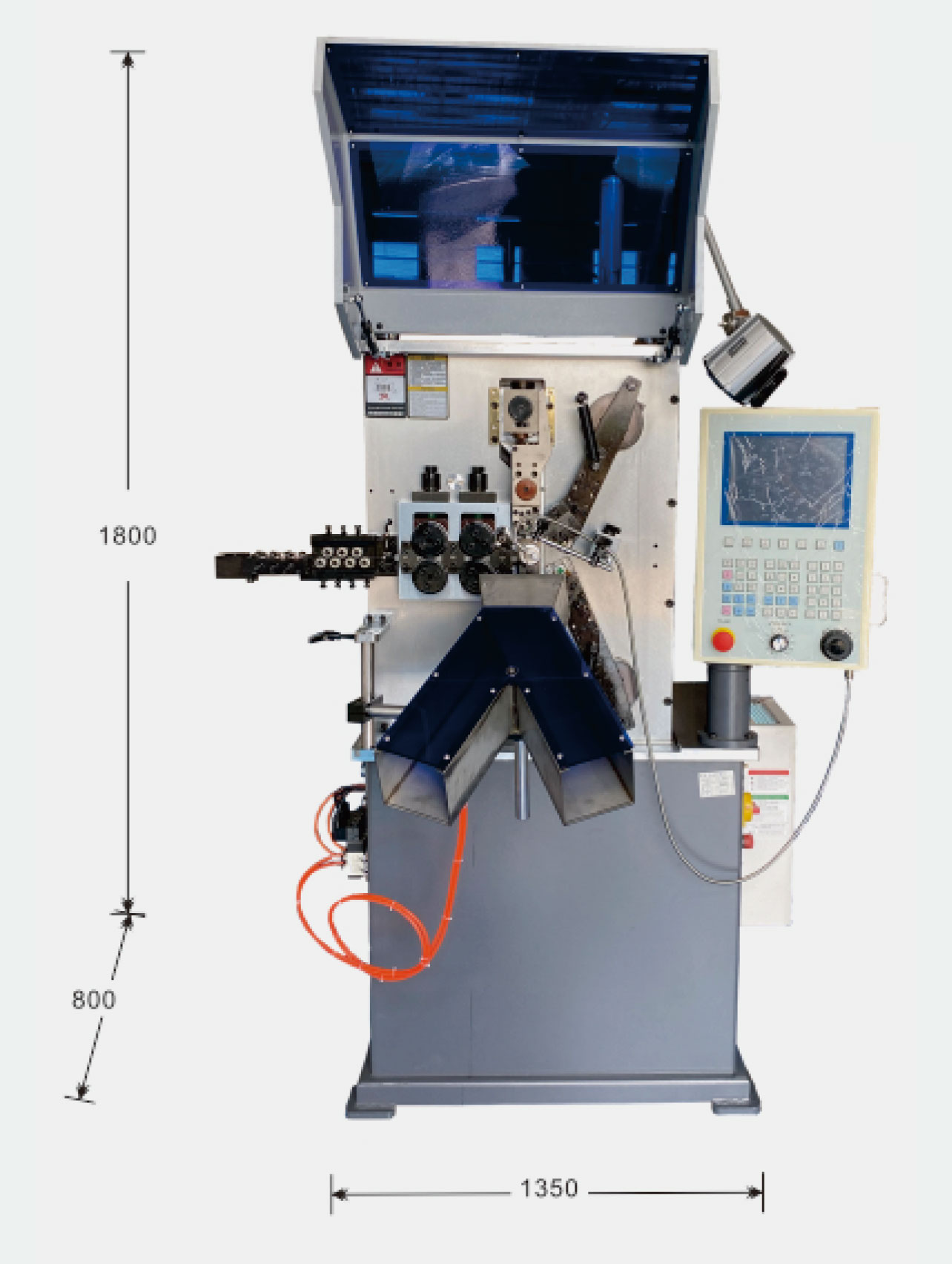

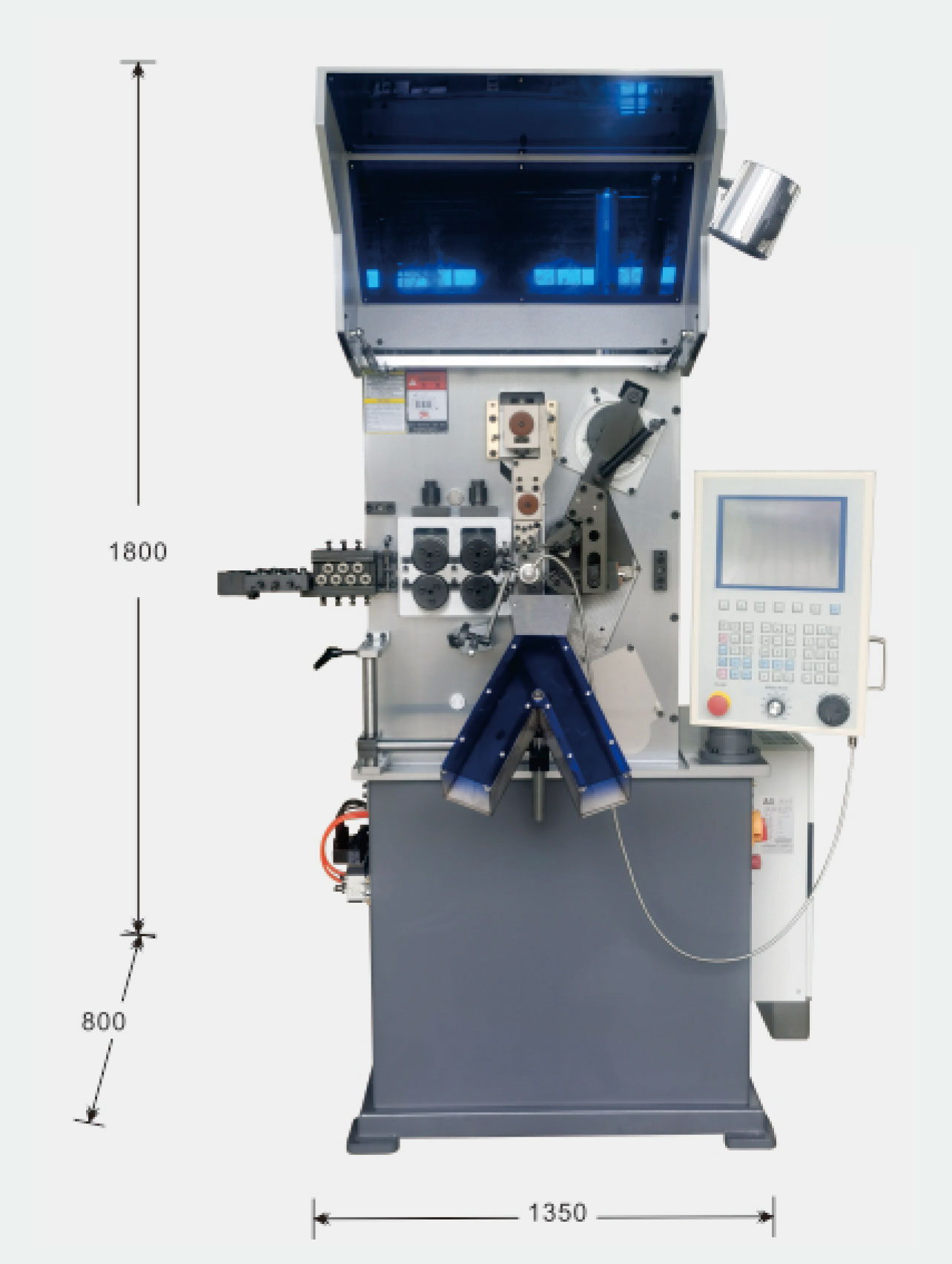

Stalwart Machinery is one of the leading Spring Coiling Machine Manufacturers in India and Suppliers in India, We specialize in designing and delivering high-performing, custom spring coiling machines with user-friendly operation to ensure maximum productivity and consistent production output. offered machines are engineered to coil metal wire into spring with the superior accuracy, which cater to divers industrial needs

We have used new technological updates in these springs coiling machine and it gives higher productivity as compared to manual labor. These are mainly used in automotive industrial sectors for making suspension spring, valve springs and clutch springs also. The use of our new CNC spring coiling machine increases the performance in large industrial sectors and gets work done more precisely. Let’s check out its multiple types of machines, it’s using benefits and applications also.

Types of Spring Coiling Machine

As renowned spring coiling machine manufacturers in India, we are providing the new technological machines that are highly useful in multiple applications. Here we have listed down some types such as:

- Compression Spring Coiling Machine: Our new technological spring coiling machine are specially customize for manufacturing high quality of compression spring with more accuracy and used in multiple types of applications such as suspension systems, valves, medical devices and consumer electronics. We have used servo motor technology in these springs coiling machine for wire feeding, coiling and cutting also.

- High Speed Spring Coiling Machine: Our high-speed coiling machines focus on maximizing production rates while maintaining exceptional accuracy. These are mainly used for mass production and applied in large industrial sectors. We've incorporated multi-axis control systems in these machines for controlling the overall mechanism simultaneously. They are primarily used in large-scale production of mattress and upholstery springs, and small compression springs for electronic devices.

- In-Line Spring Coiling Machines: These In-Line spring coiling machines are primarily used for minimizing manual work and increasing automation with higher accuracy. We've implemented a fully automatic feeding system mechanism in these machines for reducing downtime and streamlining the wire input process. Our machines are highly utilized in integrated assembly lines within the automotive and aerospace sectors.

- Wave Spring Machine: These wave spring machines are used for making wave springs, which are compact, lightweight, and ideal for applications requiring high load-bearing capacity and space-saving designs. The advanced wave forming algorithms in these machines ensure higher accuracy with consistent pitch and force distribution. Our machines are highly demanded by the aerospace and defense industries, which require compact and powerful spring designs.

Technical Specifications of Spring Coiling Machine

For more technical information about our Spring Coiling Machine, we have mentioned below a technical chart such as:

| Feature | Compression Spring Coiling Machine | High-Speed Spring Coiling Machine | In-Line Spring Coiling Machines | Wave Spring Machine |

|---|---|---|---|---|

| Control System | CNC with multi-axis control | High-speed CNC with servo motor | Fully automated with PLC & CNC | Advanced CNC wave-forming algorithms |

| Wire Diameter Capacity | 0.2mm – 20mm | 0.1mm – 10mm | 0.2mm – 15mm | 0.2mm – 6mm |

| Production Speed | Medium to high (1,000–5,000 springs/hr) | Ultra-high (5,000–20,000 springs/hr) | High (Integrated with production lines) | Medium (500–3,000 springs/hr) |

| Wire Feeding System | Servo-driven wire feeding | Precision high-speed servo feeder | Automated inline feeder | High-precision stepper motor control |

| Coiling Accuracy | ±0.02mm | ±0.01mm | ±0.015mm | ±0.02mm |

| Spring Index Range | 3 – 15 | 4 – 12 | 3 – 18 | 2 – 10 |

| Production Speed (springs/hr) | 1,000 – 5,000 | 5,000 – 20,000 | 3,000 – 12,000 | 500 – 3,000 |

| Control System (Axes) | CNC (3–6 axes) | High-speed CNC (4–8 axes) | PLC & CNC (4–10 axes) | Advanced CNC (3–6 axes) |

| Feeding Mechanism | Servo motor | High-speed servo | Automated inline feeder | Precision stepper motor |

| Wire Feeding Speed (m/min) | 30 – 120 | 50 – 200 | 40 – 150 | 20 – 80 |

| Coiling Accuracy (mm) | ±0.02 | ±0.01 | ±0.015 | ±0.02 |

Features of Spring Coiling machine

As a leading spring coiling machine suppliers in India, our all types of machines are known for their advanced features and gives multiple types of benefits such as:

- Adaptive Coil Cutting and Bending Mechanism: Our all-types of spring coiling machines integrate cutting tools and bending arms for automatic adjustment of coil tension and material properties.

- High-Speed Production & Efficiency: We've incorporated new advanced motorized components and optimized coil winding algorithms to enable high-speed operation.

- Smart Wire Feeding System: All our spring coiling machines feature a programmable wire feed with real-time feedback, ensuring greater accuracy and minute detail.

- Automatic Lubrication System: To minimize maintenance costs and ensure smoother operation, we've integrated automatic lubrication system technology into these machines, which extends machine life and reduces downtime.

Applications of Spring Coiling Machine

One of the leading CNC spring coiling machine Suppliers in India, these machines are largely used in various kind of applications such as:

- Aerospace landing gear, missile, and satellite springs

- Electronics micro-springs for circuits and connectors

- Automotive suspension, clutch, and engine valve springs

- Industrial automation, conveyors, and heavy machinery springs

- Medical stents, surgical tools, and orthopedic springs

- Robotics actuators, AI components, and automation springs

- Appliances, power tools, and mechanical device springs

- Defense precision coil manufacturing for military equipment

Stalwart Machinery LLP is a well-known reputed Spring Coiling Machine manufacturers and suppliers in India, We are committed to delivering cutting-edge edge advanced, and customized spring coiling solutions as per the customers and industry requirement at latest affordable prices in India. Our offered machines are designed by using the latest automation technology and high performing sensor equipment to ensure superior accuracy and consistency in coil manufacturing. contact us today!

Frequently Asked Questions (FAQs)

A Spring Coiling Machine is one of Machanical Device which used to Manufacturer Spring Coil by Winding the wire into the multiple shapes with the precise diameter.

A spring coiler feeds wire through rollers, bends it into coils using servo-driven tools, and cuts it to the desired lengthAdvance CNC models allow programmable control for accurate coiling

Spring coiling machine produce compression springs, tension (extension) springs, torsion springs, and custom-shaped coil springs it depending on the machine’s configuration and CNC Automation

Production speed vary by model to model and spring complexity and requirement but can range from 100 to over 1000 springs per minute for high-speed configuration machines.